Block PB 41

Application

Quick-installation element for efficiently mounting pipe clamps and other components to all Sikla Channels of the 41 series. The width is suitable for double channels also.

- Time saving due to pre-assembled block - replaces 2 indvidual parts.

- Due to the force of the integrated spring, self-supporting if used for vertical channels; can however still be easily moved along the channel by hand.

- To be combined with Pressix Rods PNS, Grub Screws, Bolts and other threaded elements.

Scope of delivery

Pre-assembled (flange nut enclosed)

Installation

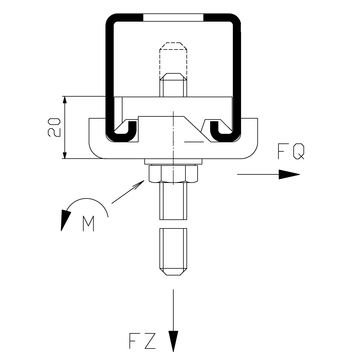

Insert the Block into the channel; by turning the Holding Bracket by 90° to the right, the Channel Nut locks into the stop position; then tighten flange nut or other connecting part - the job is done!

Note: Minimum screwing depth from the lower edge of the Holding Bracket = 20 mm.

Technical Data

The permissible load is determined by the threaded (grooved) rods used. Also the point carrying capacity of the channel and its torsional moment must not be exceeded.

These values can be found in the technical data sheets of the respective products.

| Min. material thickness Channel MS 41 [mm] | FZ * [kN] | FQ * [kN] |

|---|---|---|

| 1.5 | 2.0 | 2.0 |

| 2.0 | 4.0 | 2.5 |

| 2.5 | 6.0 | 2.5 |

| 3.0 | 7.2 | 2.5 |

Perm. load FZ * under stress of fire

| Min. material thickness Channel MS 41 [mm] | FWD 30 [N] | FWD 60 [N] | FWD 90 [N] | FWD 120 [N] |

|---|---|---|---|---|

| 2.0 | ≤ 850 | ≤ 430 | ≤ 250 | |

| ≥ 2.5 | ≤ 1000 | ≤ 540 | ≤ 350 | ≤ 250 |

| FZ = | max. permissible tensile load |

| FQ = | max. permissible lateral force against displacing |

| M = | Tightening moment of the flange nut or of another connecting component for reaching the lateral force FQ (applicable to all Grub Screws of class 4.6 and greater without grooves in the tightening area) |

* The load capacity of the connecting parts used is to be considered. This applies particularly under stress of fire.

| Material: | Steel, electro-galvanised |